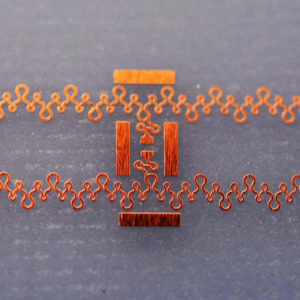

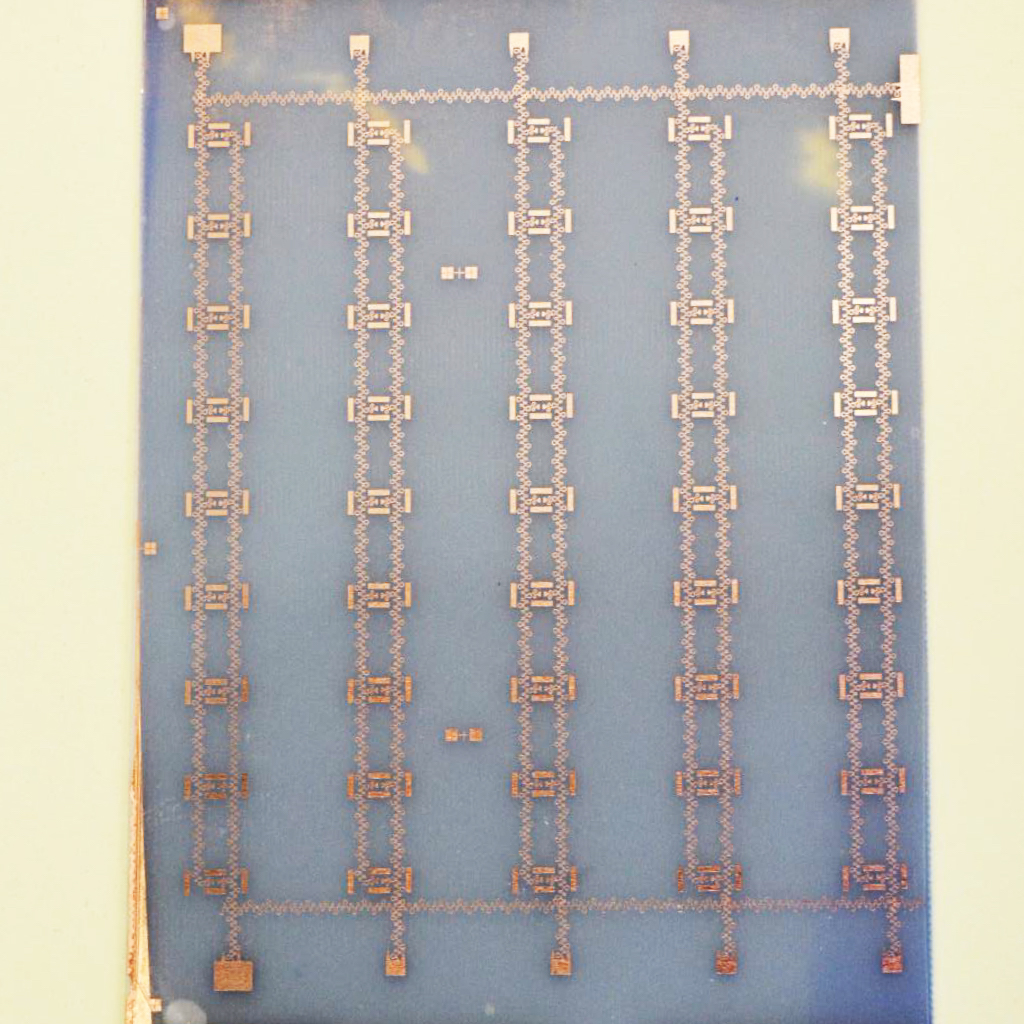

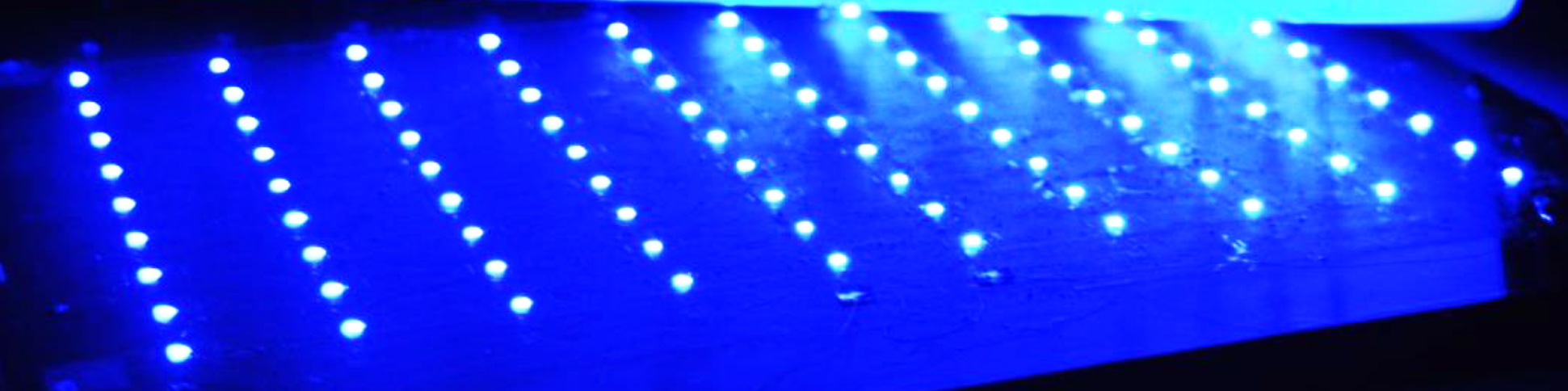

We can fabricate circuits on different rigid substrates such as Si or glass epoxy using conventional printed circuit board technology or micro-fabrication technique. The resolution of the circuit depends on the demand. We can achieve a minimum resolution of 10 micrometers. Below this is also possible if needed. Some of our current prototypes are shown below.

Manufactured prototypes

Our manufacturing process uses highly trained engineers and advanced automated/semi-automated tools to ensure the quality of the products and to satisfy our customer’s needs. Every product is tested individually.

Our standard manufacturing process uses high quality copper cladded rigid glass epoxy. Depending on the customer's need, the copper thickness can be adjusted. For multilayer circuit boards the metal thickness can be different in each active layer.

The circuit design is printed on the board following a number of fabrication processes that uses highly skilled engineers, technicians, and advanced tools. Each board is tested before assembling the devices to ensure the quality and functionality. Please, note that we do not check the circuits or designs provided by the customer unless requested. If needed, our skilled engineers can check your circuit design before production which require additional service charge.

The final product ensures the requirements of the users or the customers. Depending on the devices, we test and calibrate individual item where necessary. Please note that we are not responsible or do not guarantee any fault in the circuit since we do not check the design by default. If you need to check the circuit by our engineers contact us before ordering.